PRODUCTS

-

FENTON MEMBRANES

-

FENTON OIL SKIMMERS

-

FENTON AGITATORS

- FENTON BAR SCREENS

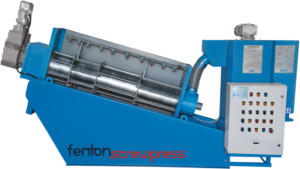

- FENTON SCREW PRESS

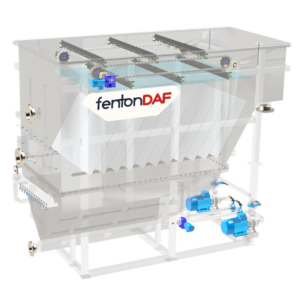

- FENTON DAF

- FENTON RING BLOWERS

- PIPE FLOCCULATOR

- SWIMMING POOL EQUIPMENTS

MBR Membrane Bioreactor

Fenton Technologies takes pride in introducing our innovative product, the Fenton Technologies MBR Membrane. Designed to revolutionize water treatment processes, our MBR Membrane offers advanced filtration technology for superior efficiency and water purification.

The Fenton Technologies MBR Membrane is a cutting-edge filtration solution that combines the power of Membrane Bioreactor (MBR) technology with advanced membrane filtration. It serves as a selective barrier, effectively removing solids, bacteria, and contaminants from water to ensure optimal purification.

Applications of Fenton Technologies MBR Membrane

- Municipal Wastewater Treatment Plants

- Industrial Effluent Treatment

- Decentralized Wastewater Treatment Systems

- Water Reuse and Recycling Projects

- Resort and Hotel Water Treatment

- Food and Beverage Industry Water Purification.

Features Of MBR Membrane

- Meet the higher standard of permeate water quality

- Lower Filtration pressure and energy saving

- Stronger Chemical resistance, easily clean

- Good Hydrophilicity and strong fouling resistance

- High standard of bio mass/solids control

- Lower component Cost and less components

- Modular system design, easy assembly.

Fenton oil skimmer

Fenton Technologies Oil Skimmer is a highly efficient device specifically designed for oil removal from water surfaces. It utilizes advanced technology to effectively and continuously remove oil, grease, and other hydrocarbon pollutants, thereby preventing contamination and preserving the integrity of water ecosystems.

Key Features of Fenton Technologies Belt Type Oil Skimmer

- Efficient Oil Removal: Our oil skimmer is equipped with a specially designed collection mechanism that efficiently removes oil from water surfaces. It effectively separates and collects floating oil, leaving the water clean and free from hydrocarbon contaminants.

- Versatile Applications: The Fenton Technologies Oil Skimmer is suitable for a wide range of applications, including industrial wastewater treatment, oil spill response, stormwater management, and water treatment in various industries. It can be customized to meet the specific needs of different environments.

- Highly Durable and Low Maintenance: Built with durable materials, the Fenton Technologies Oil Skimmer is designed to withstand harsh environmental conditions and heavy usage. Its robust construction ensures long-lasting performance with minimal maintenance requirements.

- Adjustable Skimming Capacity: Our oil skimmer offers adjustable skimming capacity, allowing for efficient oil removal in different water volumes and oil spill scenarios. The skimming rate can be easily customized to achieve optimal performance based on specific requirements.

- Ease of Installation and Operation: The Fenton Technologies Oil Skimmer is designed for easy installation and operation. It can be integrated into existing water treatment systems or deployed as a standalone unit, providing flexibility and convenience.

Applications of Fenton Technologies Belt Type Oil Skimmer

- Industrial Wastewater Treatment

- Oil Spill Response and Recovery

- Stormwater Management

- Manufacturing and Processing Facilities

- Power Plants and Refineries

- Marine and Coastal Environments.

agitators

Fenton Technologies Agitators are robust and versatile devices used for mixing, blending, and stirring applications across different industries.

Fenton Technologies Agitators, a range of high-performance equipment designed to enhance mixing and stirring processes. Our agitators are engineered to deliver efficient and reliable agitation, ensuring optimal blending and homogeneity in various industrial applications.

Key Features of Fenton Technologies Agitators

- Efficient Mixing Capability: Fenton Technologies Agitators are designed to deliver efficient mixing capabilities, ensuring thorough blending and homogeneity of substances. They effectively agitate liquids, suspensions, and slurries, minimizing settling, segregation, and stratification.

- Wide Range of Agitation Options: Our agitators offer a wide range of agitation options, including axial flow, radial flow, and mixed flow patterns. This flexibility allows for customized agitation solutions tailored to specific process requirements.

- Durable Construction: Fenton Technologies Agitators are constructed with high-quality materials to withstand demanding industrial environments. They are built to be robust, reliable, and resistant to corrosion, ensuring long service life and minimal maintenance.

- Adjustable Speed and Power: Our agitators feature adjustable speed and power settings, providing precise control over the agitation process. This enables operators to optimize mixing conditions, adapt to varying viscosities, and achieve desired results.

- Easy Installation and Maintenance: Fenton Technologies Agitators are designed for easy installation, minimizing downtime during setup. They are also user-friendly when it comes to maintenance, with accessible components and simple troubleshooting procedures.

Applications of Fenton Technologies Agitators

- Chemical Processing

- Pharmaceuticals

- Food and Beverage

- Water Treatment

- Cosmetics and Personal Care

- Paints and Coatings

- Petrochemicals

- Pulp and Paper

Fenton Agitators

Jet Mixer Agitator

Heavy Duty Agitator

Co-Axial Agitator

Bar Screen

Bar Screen

A bar screen is a type of mechanical equipment used in wastewater treatment plants to remove large objects and debris from raw wastewater before it enters the treatment process.

Fenton Technologies Bar Screen is a robust and versatile mechanical device used for solid separation in water treatment applications. It consists of a series of parallel bars or rods set at a specific spacing to capture and remove solid materials from the wastewater flow, ensuring the smooth operation of treatment processes.

Fenton Technologies Bar Screen, a reliable and efficient solution for solid separation in water treatment processes. Our bar screen is designed to effectively remove debris, solids, and large particles from wastewater, ensuring optimal flow and preventing clogging in downstream treatment systems.

Key Features of Fenton Technologies Bar Screen

- Efficient Solid Separation: Fenton Technologies Bar Screen is engineered to efficiently separate and remove debris, solids, and large particles from wastewater. It effectively prevents these materials from entering downstream treatment systems, protecting equipment and ensuring optimal process performance.

- Rugged Construction: Our bar screens are constructed with high-quality materials, making them durable and resistant to corrosion. They can withstand harsh operating conditions and provide reliable performance over extended periods, minimizing maintenance requirements.

- Flexible Bar Spacing Options: Fenton Technologies Bar Screen offers flexible bar spacing options to accommodate different wastewater characteristics and flow rates. This adaptability allows for effective solid separation in a wide range of applications.

- Self-Cleaning Mechanism: Our bar screens are equipped with a self-cleaning mechanism, such as rotating brushes or spray jets, to remove captured solids from the bars. This feature ensures continuous operation without manual intervention, reducing downtime and optimizing efficiency.

- Easy Installation and Maintenance: Fenton Technologies Bar Screen is designed for easy installation and maintenance. It can be customized to fit specific channel dimensions and can be easily accessed for cleaning, inspection, and routine maintenance tasks.

Applications of Fenton Technologies Bar Screen

- Municipal Wastewater Treatment Plants

- Industrial Wastewater Treatment

- Pump Stations

- Stormwater Management

- Combined Sewer Overflow (CSO) Systems

- Water Intake Structures

Type of Fenton Bar Screens

- Automatic Basket BarScreen

- Manual Basket BarScreen

- Manual Bar Screen

- Mechanical Drum Screen

Screw Press

Screw Press

A screw press machine is a mechanical device that uses a screw or worm to exert pressure on a material in order to extract juice, oil, or other liquids from it, or to compress solids.

Fenton Technologies Screw Press is a robust and versatile equipment used for solid-liquid separation. It utilizes a screw mechanism to gradually compress and dewater sludge, extracting water from the solids and producing a dewatered cake with reduced moisture content. This innovative technology offers a cost-effective and sustainable solution for waste management.

Key Features of Fenton Technologies Screw Press

- Efficient Dewatering Capability: Fenton Technologies Screw Press excels in efficient dewatering of sludge and solids. The screw mechanism applies gradual pressure to the sludge, squeezing out water and reducing the moisture content, resulting in a dewatered cake with improved handling characteristics.

- Continuous Operation: Our screw press is designed for continuous operation, ensuring a consistent and reliable separation process. It can handle high volumes of sludge and operate seamlessly, minimizing downtime and optimizing productivity.

- Flexible Design Options: Fenton Technologies Screw Press offers flexible design options to accommodate different applications and specific requirements. It can be customized with various screw configurations, sizes, and materials to suit the characteristics of the sludge or solid waste being processed.

- Minimal Energy Consumption: Our screw press is engineered for energy efficiency, minimizing power consumption during operation. It utilizes a low-speed screw mechanism that reduces energy requirements while maintaining high dewatering efficiency.

- Easy Maintenance and Operation: Fenton Technologies Screw Press is designed for ease of maintenance and operation. It features a user-friendly interface and accessible components for routine cleaning, maintenance, and troubleshooting tasks, ensuring smooth and hassle-free operation.

Applications of Fenton Technologies Screw Press

- Wastewater Treatment Plants

- Industrial Sludge Dewatering

- Food Processing Waste Management

- Agricultural Waste Management

- Biogas and Biofuel Production

- Pulp and Paper Industry.

Advantages of Fenton Screwpress

- Continuous Operations

- Low Power Usage

- Low Noise Level

- High Cake Dryness

- Low Wash Water Requirements

![]()

Dissolved Air Flotation (DAF)Technology

Dissolved Air Flotation (DAF)Technology

DAF stands for Dissolved Air Flotation, which is a wastewater treatment technology used to remove suspended solids, fats, oils, and greases from industrial and municipal wastewater streams.

Fenton Technologies Dissolved Air Flotation (DAF) System is a reliable and versatile water clarification system. It employs a combination of dissolved air, chemicals, and mechanical separation to effectively remove contaminants from water. A concentrated sludge layer is then removed as a result of the system's creation of microscopic air bubbles that stick to the suspended particles and cause them to float to the surface.

Key Features of Fenton Technologies DAF System

- Efficient Solid-Liquid Separation: Fenton Technologies Dissolved Air Flotation System offers efficient solid-liquid separation, effectively removing suspended solids, oils, grease, and other contaminants from water. It ensures the production of clarified water with reduced turbidity and improved water quality.

- Optimized Bubble Generation: Our DAF system utilizes optimized bubble generation techniques to create fine air bubbles for effective particle attachment. This maximizes the flotation efficiency and enhances the removal of even the smallest particles from the water.

- Flexible Design Options: Fenton Technologies Dissolved Air Flotation System offers flexible design options to accommodate varying flow rates, water characteristics, and application requirements. It can be customized with different tank sizes, plate spacings, and sludge handling mechanisms to suit specific project needs.

- Enhanced Chemical Conditioning: Our DAF system incorporates advanced chemical conditioning processes to optimize coagulation and flocculation, enhancing the removal of contaminants. This ensures efficient solids separation and improved overall performance.

- Easy Operation and Maintenance: Fenton Technologies Dissolved Air Flotation System is designed for easy operation and maintenance. It features user-friendly controls, automatic sludge removal mechanisms, and accessible components for routine cleaning, inspection, and maintenance tasks.

Applications of Fenton Technologies DAF System

- Municipal Wastewater Treatment

- Industrial Wastewater Treatment

- Oil and Gas Industry

- Food and Beverage Industry

- Pulp and Paper Industry

- Mining and Metals Industry

DAF technology is known for its high removal efficiency and effectiveness in treating wastewater with high concentrations of solids, fats, oils, and greases. It is widely used in the food and beverage, oil and gas, and pulp and paper industries, as well as in municipal wastewater treatment plants.

Air-blower

Air-blower

An air blower, also known as a diffuser or aerator, is a piece of equipment used in wastewater treatment to introduce air into the wastewater. The air helps to promote the growth of aerobic bacteria, which break down organic matter in the wastewater.

Fenton Technologies Air Blower is a versatile and robust device used for supplying clean and pressurized air in industrial environments. It utilizes a powerful motor-driven impeller to create airflow, delivering a steady stream of compressed air for a wide range of applications, including pneumatic conveyance, wastewater treatment, aeration, and more.

Key Features of Fenton Technologies Air Blower

- Reliable Air Supply: Fenton Technologies Air Blower provides a reliable and consistent air supply, ensuring uninterrupted operation of pneumatic systems and air-dependent processes. It delivers clean and pressurized air, meeting the specific requirements of different applications.

- High Performance and Efficiency: Our air blower is designed for high performance and energy efficiency. It utilizes advanced impeller technology and optimized airflow design to maximize air output while minimizing energy consumption, resulting in cost savings and reduced environmental impact.

- Low Noise Operation: Fenton Technologies Air Blower is engineered for low noise operation, reducing noise pollution in industrial settings. It features noise-reducing components and advanced vibration isolation techniques, ensuring a quieter working environment.

- Durable Construction: Our air blower is built with durable materials to withstand demanding industrial conditions. It is designed for long service life, with corrosion-resistant components that can withstand continuous operation in harsh environments.

- User-Friendly Design: Fenton Technologies Air Blower is designed with user convenience in mind. It features easy installation, intuitive controls, and accessible maintenance points, making it user-friendly and efficient to operate and maintain.

Applications of Fenton Technologies Air Blower

- Pneumatic Conveying Systems

- Aeration Processes

- Wastewater Treatment Plants

- Industrial Manufacturing

- Chemical Processing

- Food and Beverage Industry

- Energy and Power Generation

Pipe Flocculator

Pipe Flocculator

A pipe flocculator is a type of wastewater treatment equipment that uses a series of pipes to mix chemicals and water to facilitate the coagulation and flocculation of suspended solids in the water. The process involves adding chemicals such as alum or ferric chloride to the water to create tiny particles called flocs, which then combine with the suspended solids and settle to the bottom of the tank.

Fenton Technologies Pipe Flocculator is a highly effective mixing device used in water treatment applications. It utilizes a specially designed pipe configuration to create controlled turbulence and promote the collision and aggregation of particles, resulting in the formation of larger flocs. This enhanced flocculation improves the efficiency of sedimentation and filtration processes, leading to superior water quality.

Key Features of Fenton Technologies Pipe Flocculator

- Efficient Mixing and Flocculation: Fenton Technologies Pipe Flocculator ensures efficient mixing and flocculation by creating the ideal conditions for the collision and aggregation of particles. The unique pipe design and flow patterns optimize chemical reactions, enhancing the formation of larger flocs for effective solid-liquid separation.

- Uniform Flow Distribution: Our pipe flocculator is designed to provide uniform flow distribution throughout the treatment process. It ensures equal exposure of particles to the flocculation agents, promoting consistent and thorough mixing for optimal treatment efficiency.

- Modular and Scalable Design: Fenton Technologies Pipe Flocculator features a modular and scalable design, allowing for easy customization and expansion based on specific project requirements. Additional units can be added to accommodate varying flow rates and treatment capacities.

- Low Energy Consumption: Our pipe flocculator is engineered for low energy consumption. The efficient hydraulic design minimizes headloss and pressure drop, reducing the overall energy requirements and operating costs of the water treatment system.

- Easy Installation and Maintenance: Fenton Technologies Pipe Flocculator is designed for easy installation and maintenance. It can be integrated into new or existing water treatment systems, and its accessible design allows for convenient cleaning, inspection, and routine maintenance tasks.

Applications of Fenton Technologies Pipe Flocculator

- Drinking Water Treatment

- Wastewater Treatment Plants

- Industrial Water Treatment

- Municipal Water Treatment

- Surface Water Treatment

- Desalination Processes

![]()

Swimming pool Cleaning Equipments

Pool Skimmer

This is a net-like tool used to remove leaves, debris, and insects from the water's surface.

Pool Brush

A pool brush is used to scrub the pool walls and floors to remove algae and other dirt buildup.

Vacuum Head

This is attached to the vacuum hose and used to suction dirt and debris from the bottom of the pool.

Pool Vacuum Hose

This is a flexible hose that connects to the vacuum head and the pool pump to suck up debris from the bottom of the pool.

Pool Vacuum Plate

This is a special attachment that connects the vacuum hose to the pool's skimmer, allowing the pool pump to create suction.

Pool Leaf Rake

A leaf rake is a long-handled net used to scoop up leaves and other debris from the pool.

Algae Brush

This is a specialized pool brush used to scrub and remove algae growth from the pool walls and floors.

Telescoping Pole

This is an extendable pole used to attach pool cleaning equipment such as the skimmer, brush, and leaf rake.

Pool Chemical Test Kit

This is used to measure the chemical balance of the pool water, including pH, alkalinity, and chlorine levels.

Pool Water Treatment Chemicals

These include chlorine, algaecide, and other chemicals used to keep the water clean, clear, and safe for swimming.